Air driven refrigerant booster pump-SLM06

It's such a device that uses compressed air as power source, air driven refrigerant pump as pressure source and refrigerant as working medium, to get the corresponding high pressure value through regulating air drive pressure; and the ratio of output pressure to air drive pressure is 6:1.

When air drive pressure and outlet pressure reach balance, the refrigerant pump will stop pressurizing, and output pressure will be stable at the preset pressure, so it has such features: explosion-proof, output pressure adjustable, small volume, light weight, easy to operate, reliable performance, wide application range etc.

Cool operation—No heat generated during liquid transfer. Minor warming during vapor transfer.

No refrigerant heating from the motor.

Safety—Pneumatically driven. Operates from air hose like an air tool. No electrical hazard.

◪ Air driven refrigerant booster pump-SLM06

Driving air need | 2-8bar | Pressure range | 0-48bar |

Pressure ratio | 6:1 | Flow rate | 15L/min |

Driving air size | ZG1/2 | Increasing | 63mm |

Inlet size | ZG1/2 | Stroke | 60mm |

Outlet size | ZG1/2 | Noise | <75dB |

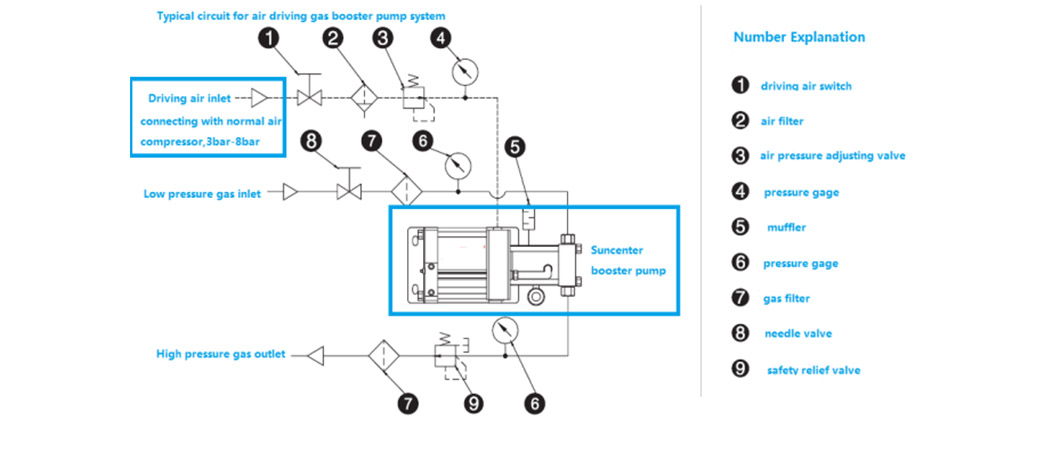

DGS- SLM06 model refrigerant pump system

◪ The standard system including following parts:

◪ SLM06 model refrigerant pump

◪ Stainless steel frame cabinet

◪ F.R.L combination for driven air (adjusts air pressure, add lubricating oil and water filter)

◪ Driven air switch (Pump starting switch), driven air pressure gauge

◪ Gas inlet switch, Gas inlet pressure gauge

◪ Gas outlet switch, Gas outlet pressure gauge, unloading valve, interconnecting pipes etc.

◪ And we could also customize it according to clients’ special requirement.

DGS- SLM06 system = SLM06 booster pump+ following valves, gages, and parts

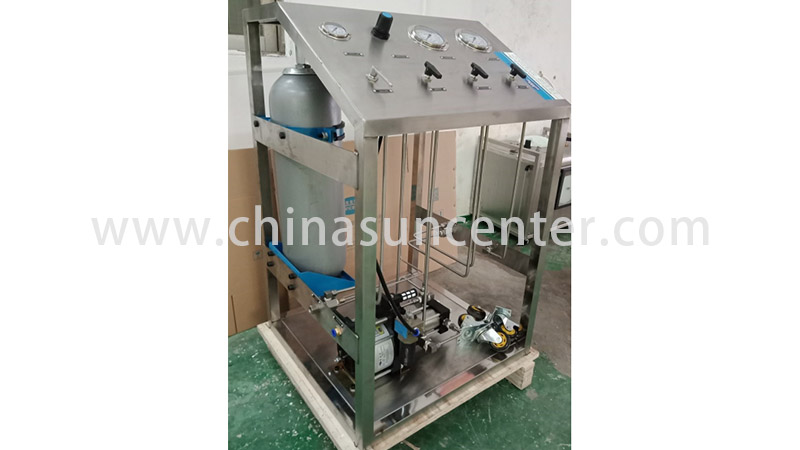

DGS- SLM06 model refrigerant pump system with 16L Accumulator

◪ DGS- SLM06 model refrigerant pump system with 16L Accumulator

DGS-SLM06 model refrigerant pumps working picture

features

It's such a device that uses compressed air as power source, air driven refrigerant pump as pressure source and refrigerant as working medium, to get the corresponding high pressure value through regulating air drive pressure; and the ratio of output pressure to air drive pressure is 6:1. When air drive pressure and outlet pressure reach balance, the refrigerant pump will stop pressurizing, and output pressure will be stable at the preset pressure, so it has such features: explosion-proof, output pressure adjustable, small volume, light weight, easy to operate, reliable performance, wide application range etc.

※ Cool operation—No heat generated during liquid transfer. Minor warming during vapor transfer.

※ No refrigerant heating from the motor.

※ Safety—Pneumatically driven. Operates from air hose like an air tool. No electrical hazard.

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | Todos los derechos reservados