Digital control hydraulic pressure test bench

Operating panel

◪ Burst hydrostatic pressure test machine for hose/pipes

Usage.

Applicable range of pressure (bursting) test equipment:

Automobile steering tube, brake pipe, air-conditioning pipe, oil pipe, water pipe cooling, radiator, heater hose, hydraulic equipment, condenser, evaporator, air conditioning filter hose, turbocharging system hose, car brake pump, a cylinder body, a project hydraulic hose, air hose and manifold, rigid pipe, joints, valves,cylinder, pressure gauges, pressure sensor,pressure vessel, pressure transmitter etc.

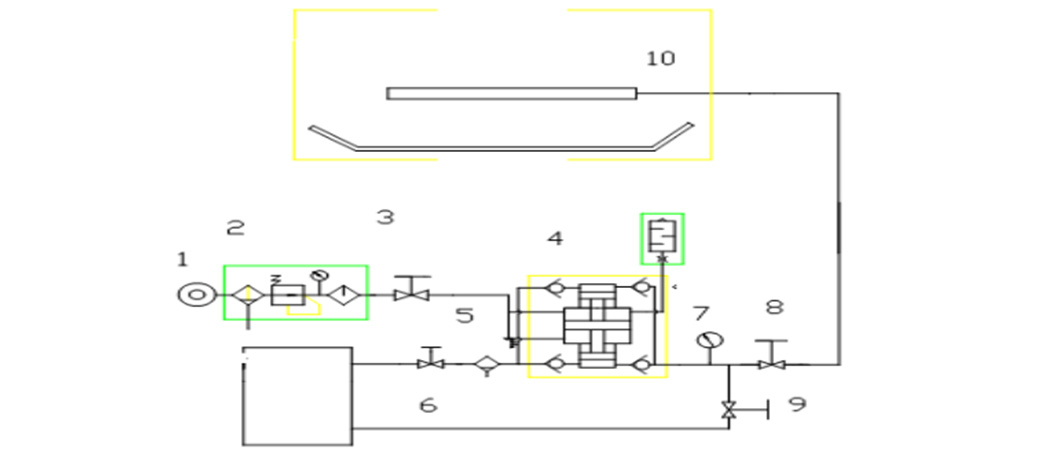

Working principle

Technical Specification

Model | Pressure Ratio | MAX Outlet | Driven Air inlet port | High pressure Outlet port | MAX Flow |

SHT-GD4-MC | 4:1 | 32 | G 1/2 | NPT/ZG | 70.0 |

SHT-GD6-MC | 6:1 | 48 | G 1/2 | NPT/ZG | 48.60 |

SHT-GD10-MC | 10:1 | 80 | G 1/2 | NPT/ZG | 30.61 |

SHT-GD16-MC | 16:1 | 128 | G 1/2 | NPT/ZG | 19.73 |

SHT-GD28-MC | 28:1 | 224 | G 1/2 | NPT/ZG | 11.30 |

SHT-GD40-MC | 40:1 | 320 | G 1/2 | NPT/ZG | 7.69 |

SHT-GD64-MC | 64:1 | 512 | G 1/2 | NPT/ZG | 4.94 |

SHT-GD80-MC | 80:1 | 640 | G 1/2 | NPT/ZG | 3.96 |

SHT-GD100-MC | 100:1 | 800 | G 1/2 | NPT/ZG | 3.13 |

SHT-GD130-MC | 130:1 | 1040 | G 1/2 | NPT/ZG | 2.4 |

SHT-GD175-MC | 175:1 | 1400 | G 1/2 | NPT/ZG | 1.81 |

SHT-GD255-MC | 255:1 | 2040 | G 1/2 | NPT/ZG | 1.23 |

SHT-GD400-MC | 400:1 | 3200 | G 1/2 | NPT/ZG | 0.79 |

SHT-G510-MC | 510:1 | 4080 | G 1/2 | NPT/ZG | 0.65 |

SHT-G800-MC | 800:1 | 6400 | G 1/2 | NPT/ZG | 0.42 |

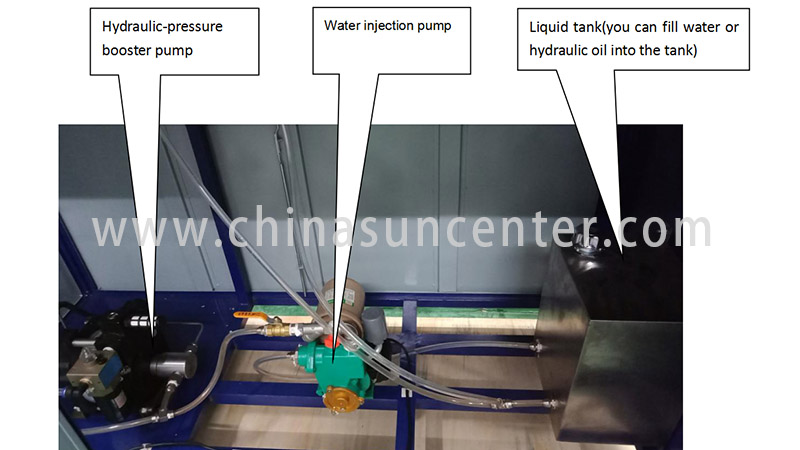

Digital control hydraulic pressure test machine working picture

◪ Digital control hydraulic pressure test machine working picture

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | Todos los derechos reservados